Well I thought I would post a couple of shots of my latest bit of homemade tool design!! - was looking for a Rivnut tool capable of inserting 6 / 8/ 10 mm Rivnuts ( steel stainless and alloy) looked around and the good tools are going for lots of money and they are huge! was looking for something handheld and have seen a couple of home made units that claimed to do the job - so I had a go!!

Used a small length of erw tube as the handle (approx 20mm OD)

1x 16mm threaded rod joiner

2x 16mm bolts (same length as 16mm joiner one bolt per rivnut size you need)

1x 8mm threaded rod joiner

8mm x 70mm socket head screw

2 x 8mm x 50mm steel bar

8mm and 6mm threaded bar 100mm long

8 and 6mm nuts and a couple of washers

bicycle rubber handlebar grip (the most expensive bit at £6 for a pair)

So the 16mm joiner is welded to the end of the tube the 8mm joiner is then welded on top of the tube about 25mm back from the joiner, then weld one of the 50mm long 8mm dia steel bars to the top of the threaded 100mm long bar at a right angle so it forms a "L" add a nut then a washer (washer should be the same outer diameter as the 16mm joiner) - now comes the hard bit if you dont have access to a lathe, you need to drill each of the 16mm bolts along its axis with whatever drill size you intend to use in rivnuts (8mm hole for a 8mm rivnut etc) so far i've got a friend to do a 6mm and 8mm versions, you will also need to face the head of the bolt to ensure its perfectly flat and level! - and thats it apart from a drop of paint and a bicycle grip added to the tube to finish it off!

Assembled as per the photos, the 8mm steel bar thats welded onto the threaded bar stops the threaded length from rotating in the drilled out bolt by resting on the side of the 8mm socket head screw mounted in the 8mm joiner the nut which is above the washer when rotated slowly pulls the threaded length up compressing the rivnut in the hole - and it works like a charm! - with this design one hand holds the rivnut flat whilst the use of a normal spanner compresses the rivnut.

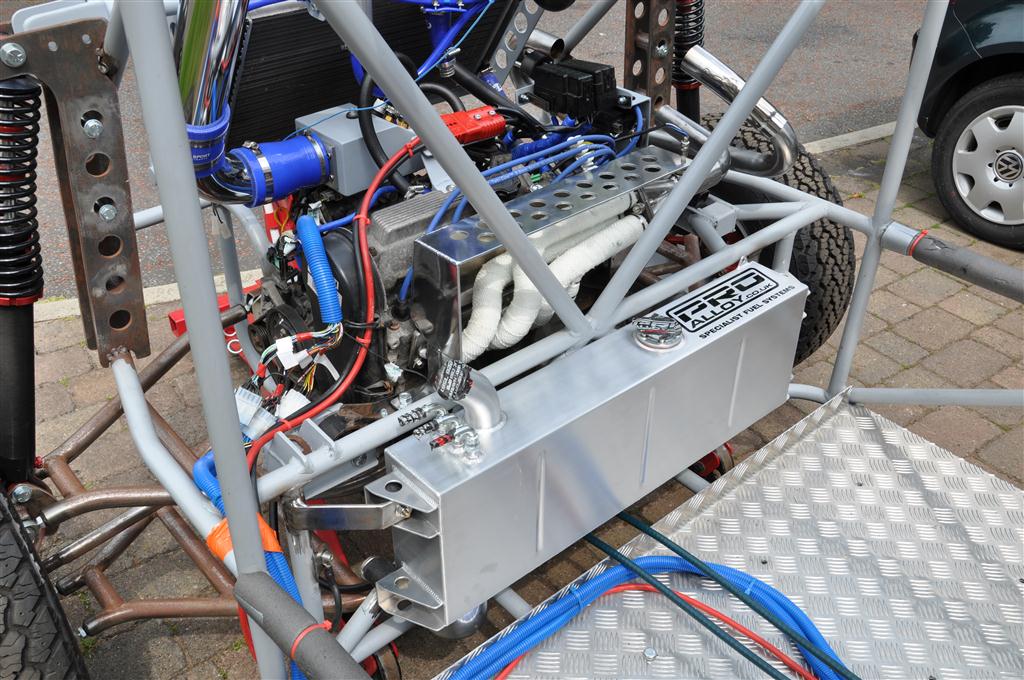

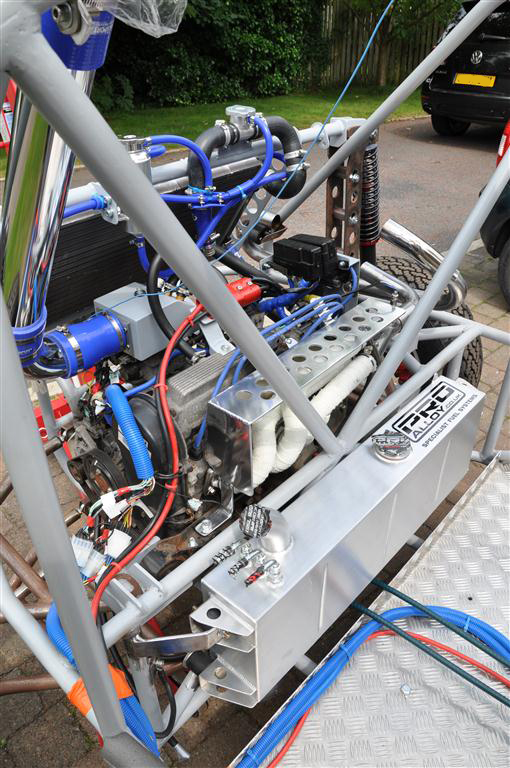

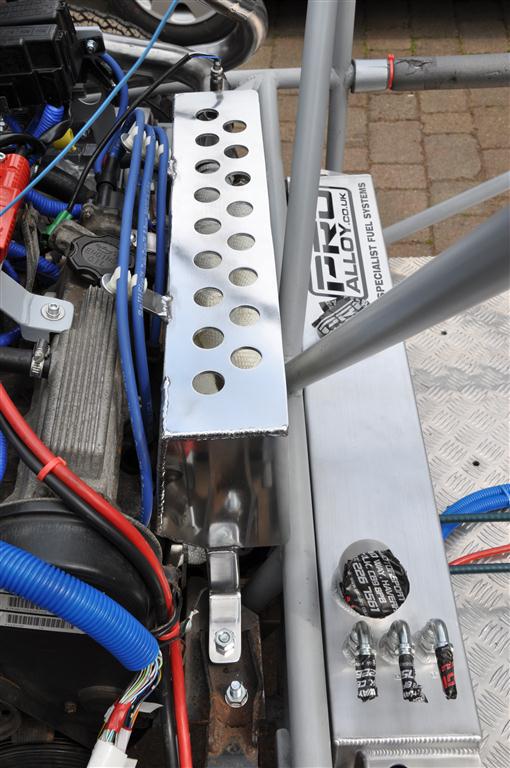

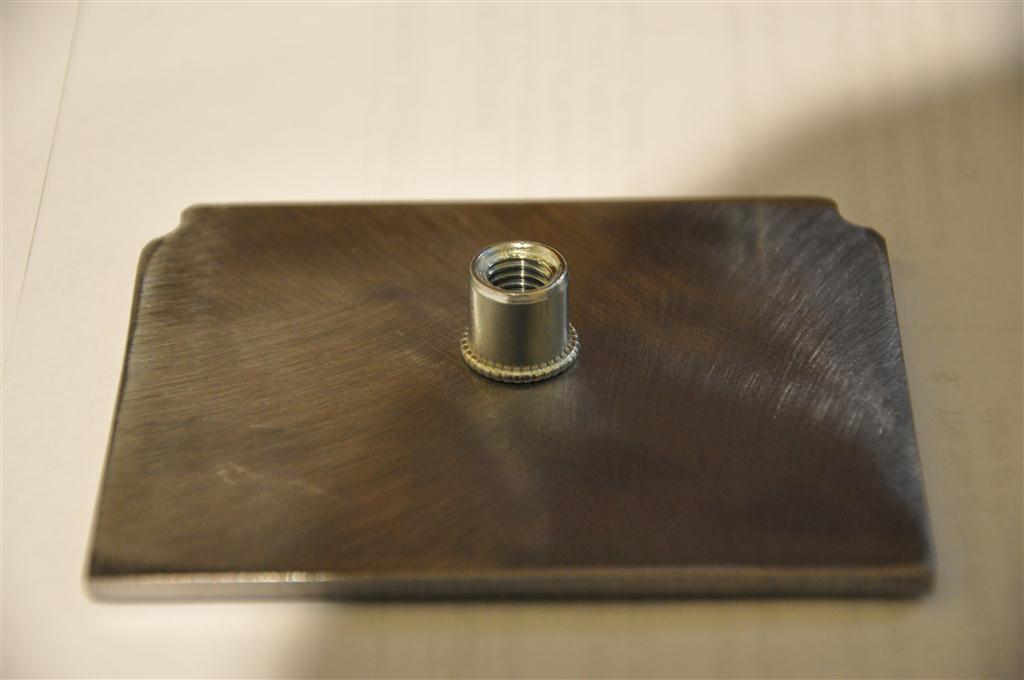

Not had chance to paint it yet but here are a few pics of it in bits and complete and also some steel rivnuts inserted into 3mm steel plate, to be honest I was not expecting the tool to work as well as it does - It will be getting a lot of use!!

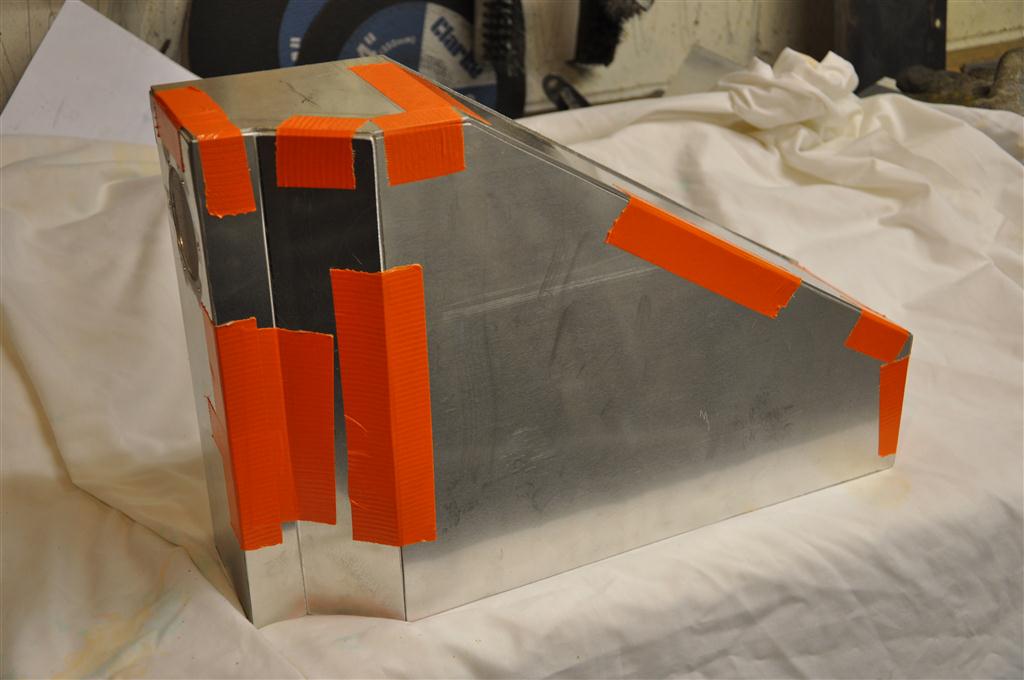

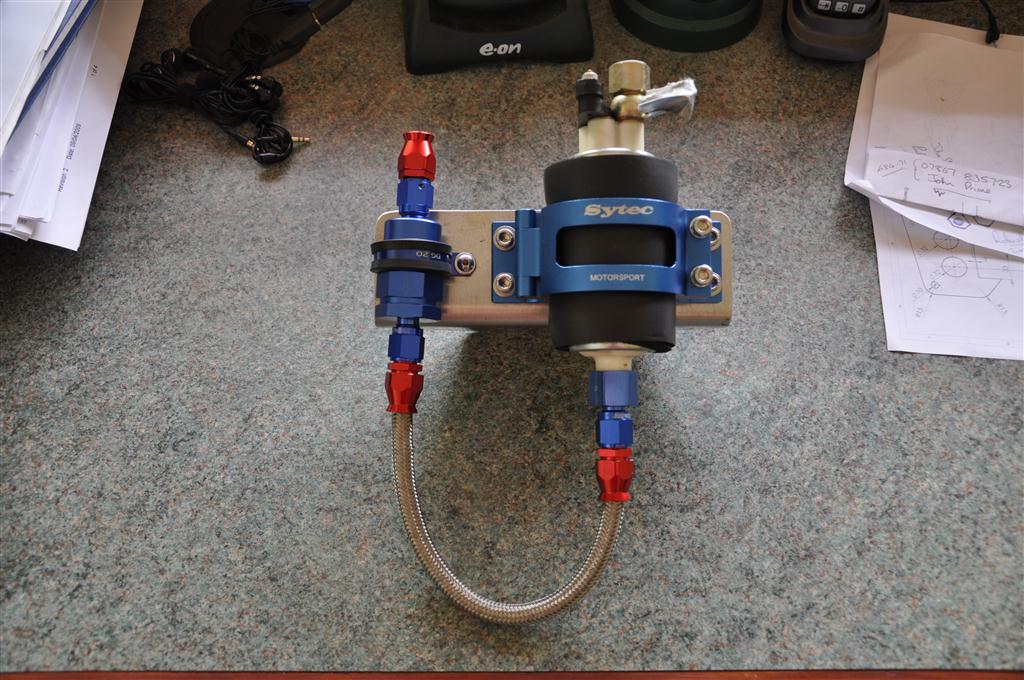

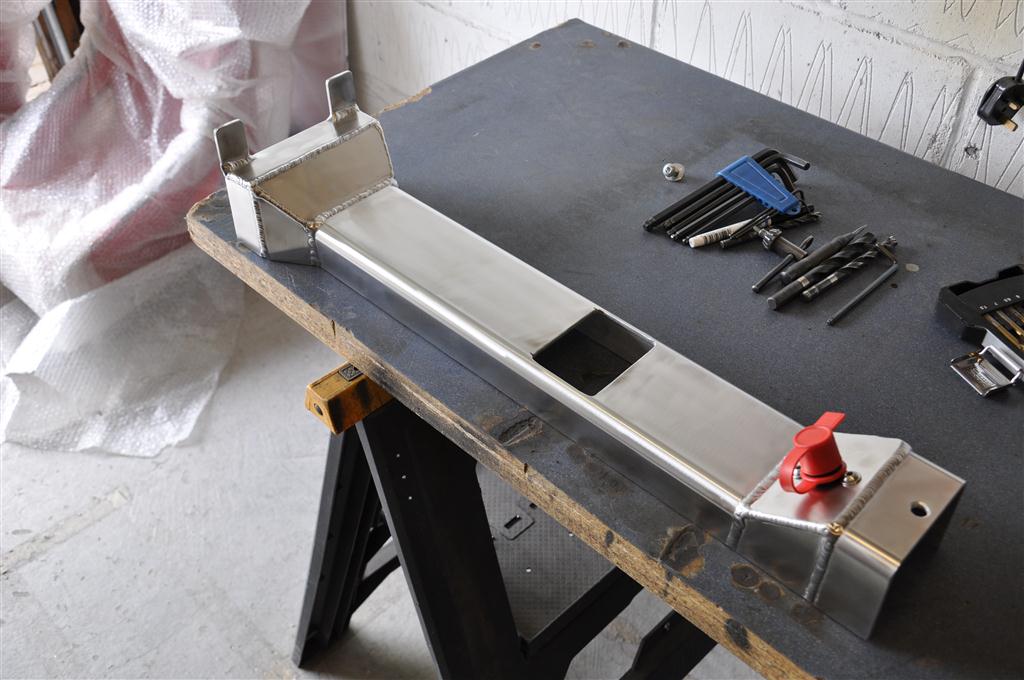

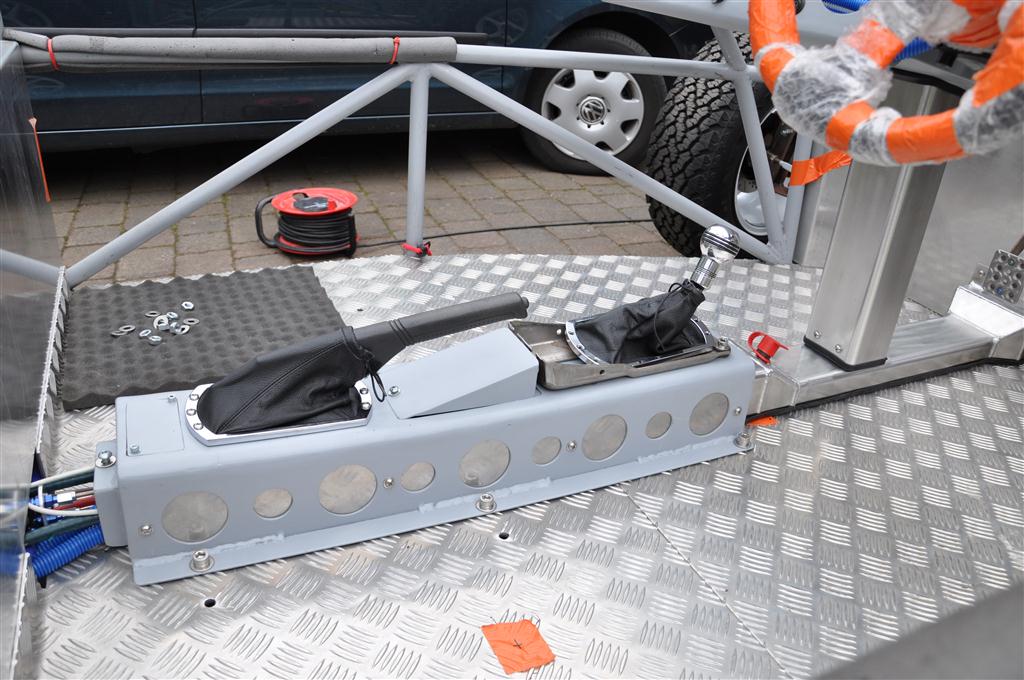

Tool parts welded up but not assembled

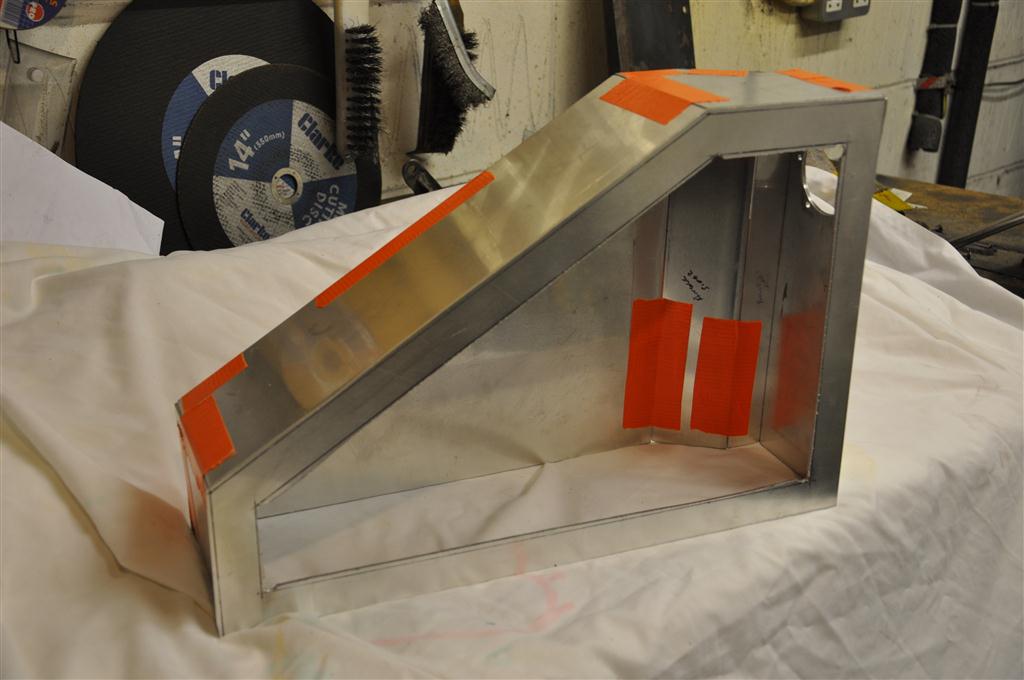

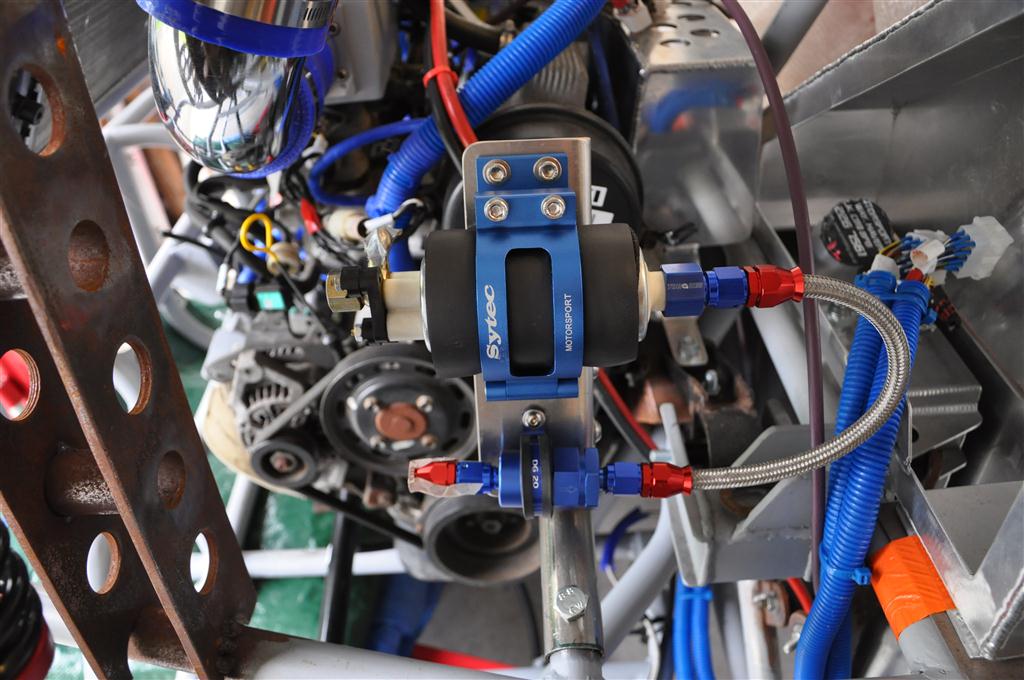

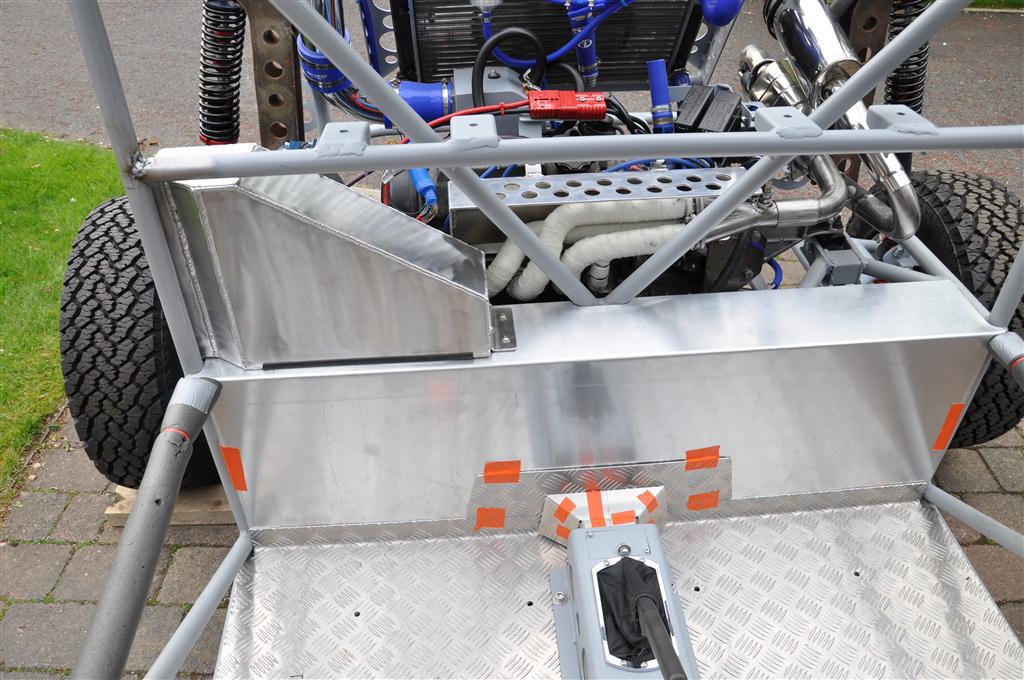

Tool Assembled

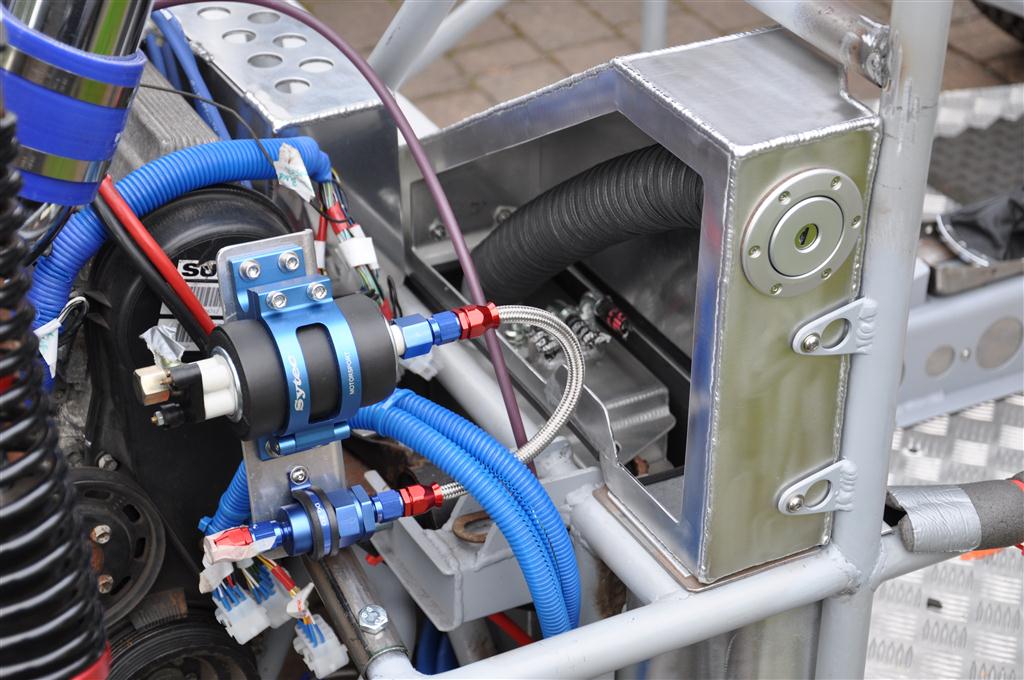

Top view of 8mm and 6mm Rivnuts inserted into two scrap bits of 3mm thick plate steel

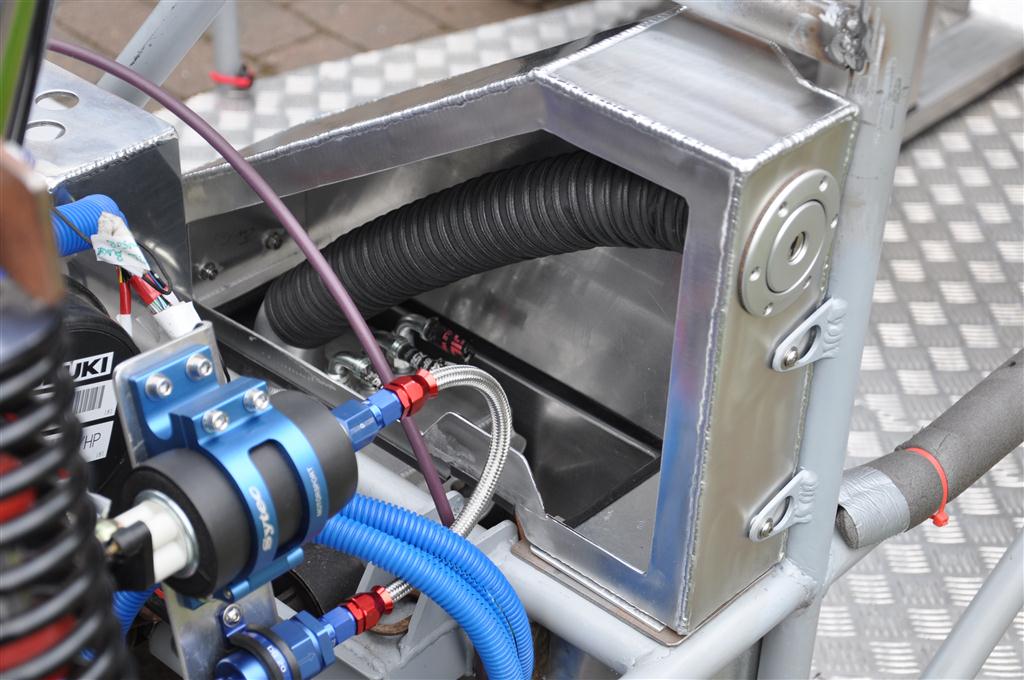

view of the underside of the 8mm rivnut showing a good even compression and solid fit.