Hi All,

Just a quick one really, while i don't have my bugy to work on i have decided to turn my attention to sorting and making a few other bits for the buggy.

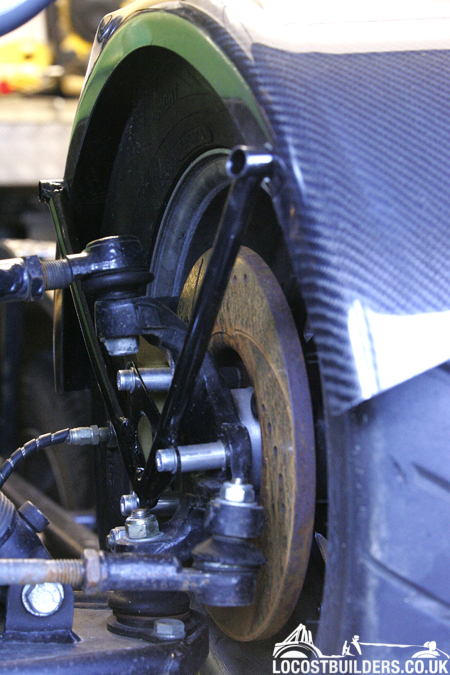

I have a set of front arch brackets and mud gaurds that i got with my buggy but they ain't the best ones i have seen. Im planning on remaking them and i am aware that several people have had their brackets snap. Does anyone know what the weak point is in the existing brackets? From what i believe they twist slightly when breaking?

Is it beacuse they are fixed to the top hub bolts and the caliper bolts as well that causes the problem?

Many thanks for any support guys

Now to work on one of my other little projects...........adjustable rear wing to help with the downforce ;D

Jason

Just a quick one really, while i don't have my bugy to work on i have decided to turn my attention to sorting and making a few other bits for the buggy.

I have a set of front arch brackets and mud gaurds that i got with my buggy but they ain't the best ones i have seen. Im planning on remaking them and i am aware that several people have had their brackets snap. Does anyone know what the weak point is in the existing brackets? From what i believe they twist slightly when breaking?

Is it beacuse they are fixed to the top hub bolts and the caliper bolts as well that causes the problem?

Many thanks for any support guys

Now to work on one of my other little projects...........adjustable rear wing to help with the downforce ;D

Jason