vexedben, well if it was me I would weld some pre drilled mounting lugs onto the frame, two for each side of the seat then bolt the angle steel to the lugs using 10mm bolts, I seem to remember that somewhere in the IVA manual it states that fixings of sufficient strength should be used and carry correct markings i.e. High Tensile 8 8 (I used the same type and strength of bolts) i made my seat mountings out of rectangular section (i think it was something like 60 x 40 with a 3mm wall) then cut out the parts/areas I didnt need till I got this:-

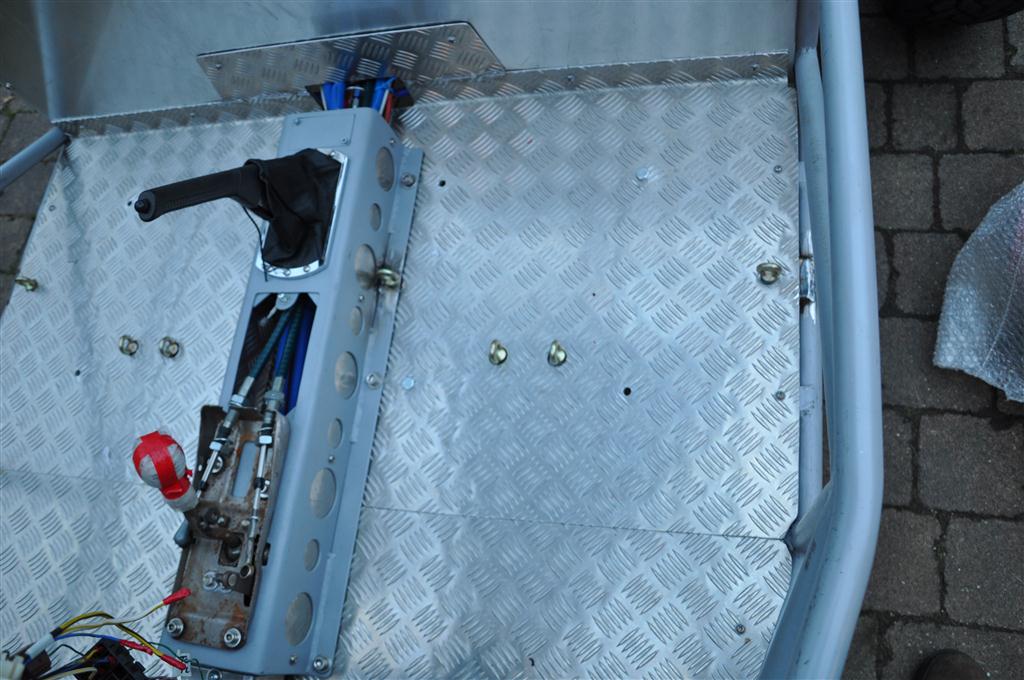

Theses two seat mounts (which in this picture have not yet been drilled ontop to fit to the rails) lift the seat from the frame a good amount and then I mount the slide rails onto the top sections which are bolted to the seat like this picture which shows everything bolted together onto the seat and through the alloy floor onto the mounting rail which is welded to the chassis:-

I use the same principle when mounting the 6 point harness's I use - weld mounting lugs to the chassis however I use a holesaw to cut a larger hole in the alloy floor so that the harness eyelet mounts directly to the steel mounting lug on the chassis - this is what I mean:-

Well just my thoughts, I always prefer to weld to the chassis rather than piercing a chassis tube !!!

Rich

Just clean and de-rust everything as thoroughly as possible then ad a nice thick coat of hammerite or some paint similar. Also when buying parts for refurbing bits and bobs, the supplier i would recommend would be minispares. Top quality service and quality parts. Never had a problem with them! Only other thing i would say is if you get stuck doing some parts, just take pictures and ask us on here

Just clean and de-rust everything as thoroughly as possible then ad a nice thick coat of hammerite or some paint similar. Also when buying parts for refurbing bits and bobs, the supplier i would recommend would be minispares. Top quality service and quality parts. Never had a problem with them! Only other thing i would say is if you get stuck doing some parts, just take pictures and ask us on here  Have fun!!

Have fun!!