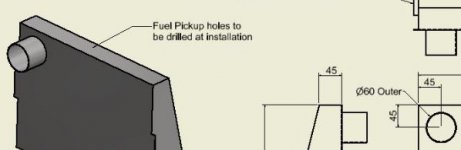

What I was meaning was you won't be able to fill it to the top as air will get trapped in the bit above the pipe inlet, put a couple of REDlines on the image but they aren't very clear.

Re the driven/freewheel, on my first buggy I had the magnet on the front offside wheel, it passed SVA, it's 12-10 years ago now but I don't think it was actually tested other than when it was driven around the yard to test self straightening. I quickly changed it though it was unreliable, the speedo would suddenly jump from 30 to 50 & back again, quite a few of us had this issue hence seeking out the terratrip option, I also had a moment when the magnet came very close to my head at around 60mph when the adhesive let go. However having said all that there are lots of car out there now with this method, it may well be the electronics are better, we were pretty early on in Acewell's history when we adopted them.

As to repeaters get some of those low profile stick on ones, bring the wires through the edge trim & then bond them to the inside of the arch with silicon

Re the driven/freewheel, on my first buggy I had the magnet on the front offside wheel, it passed SVA, it's 12-10 years ago now but I don't think it was actually tested other than when it was driven around the yard to test self straightening. I quickly changed it though it was unreliable, the speedo would suddenly jump from 30 to 50 & back again, quite a few of us had this issue hence seeking out the terratrip option, I also had a moment when the magnet came very close to my head at around 60mph when the adhesive let go. However having said all that there are lots of car out there now with this method, it may well be the electronics are better, we were pretty early on in Acewell's history when we adopted them.

As to repeaters get some of those low profile stick on ones, bring the wires through the edge trim & then bond them to the inside of the arch with silicon